Heat treatment

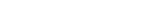

Heat treatment is a phytosanitary process designated and used for elimination of living pest in wooden material. Our company strictly comply an international norm FAO ISPM 15 that sets specific standards for the production and regulation of wood packaging material at international trade, including the correct process of hear treatment: The wooden packaging must be heated up to at least 56° Celsius for at least 30 minutes, which ensures the treatment will get to the core, not just the surface of the wood.

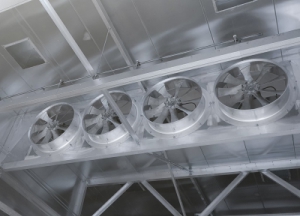

We use our own drying chambers that comply with the standards set by Central Inspection and Testing Institute of Agriculture. All the treated wooden material is labeles with IPPC standard mark and marked with our licence number CZ – 0356. Our products are supplemented with certificates drawn by SRS (State Phytosanitary Administration).

Attention! Heat treatment doesn´t mean drying or protection against fungal infestation and mold!

The sole process of heat treatment does not guarantee protection against mold, even when alll required condition are met. This is because the remnants of moisture inside the treated wood can in fact initiate the growth of mold or fungi when heated. The only way to minimize problems with mold is to combine the heat treatment with the process of drying. This increases the overall costs as the drying process itself is energy-intensive and more time-consuming procedure.

© 2024 Talpa, spol. s r. o.

© 2024 Talpa, spol. s r. o.